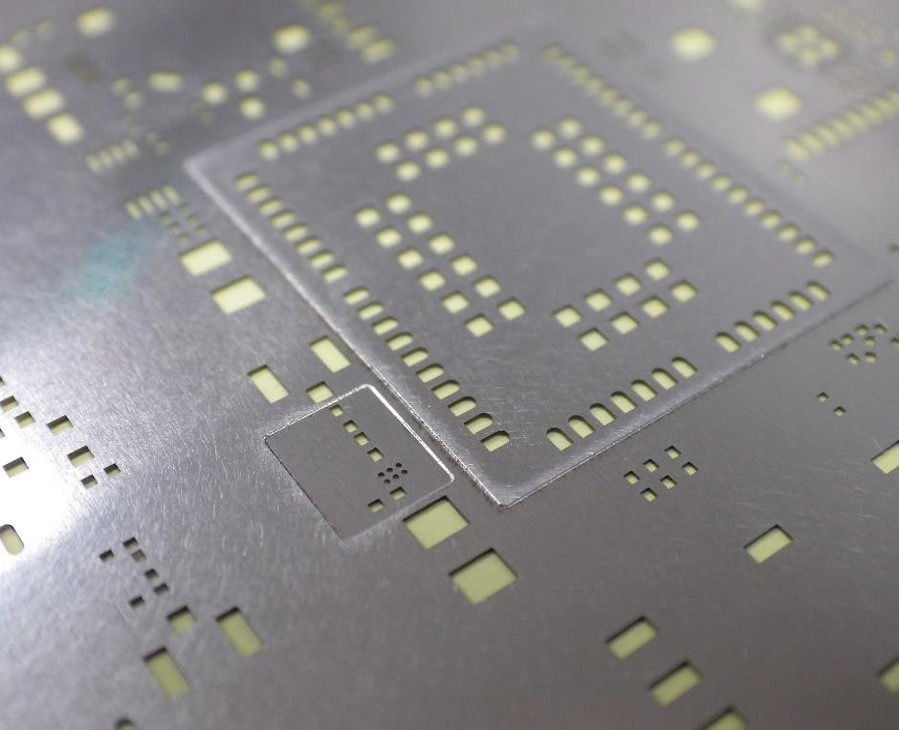

STEPPED STENCILS BY LASER WELDING

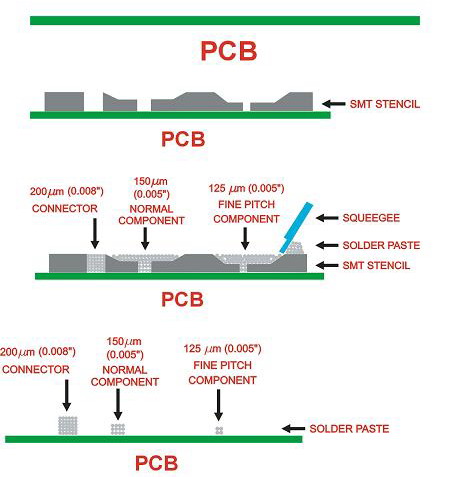

Usefull for these cases:

The first one is to print solder paste on two several thicknesses in the same stencils.

The second one is to save the thickness because peelable ink, graphite, silver contacts, etc…

This process is made by a selective welding that joint the different thicknesses in the stencil. because there is no chemical or mechanical grinding, there is no loss of flatness.

The total thickness across the entire stencil does not exceed ± 2%. The delivery time is 24 hours.

STEPPED STENCILS BY CNC MILLING

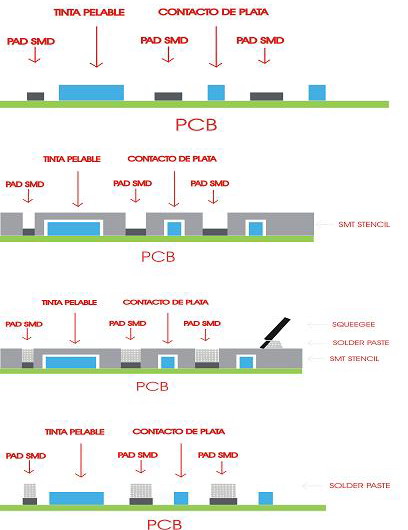

Usefull for these cases:

The first one is to print solder paste on two several thicknesses in the same stencils.

The second one is to save the thickness because peelable ink, graphite, silver contacts, etc…

By a Computer Numerical Control milling process we can to reduce the thickness of the stainless steel sheet to reach a second lower level at desired areas. With the new modern CNC miling machines we can to ensure a total accuracy in Z axis that leaves an imperceptible trace of tool use.

Especially suitable when a large number of zones at different levels are required.

The delivery time is 4 working days.